Project Information

- Industry: Manufacturing

- Company Size: 150 employees

- Project Duration: 6 months

- Services: AI Integration, Data Cleansing, App Development

- Results: 40% efficiency increase

Complete Digital Transformation

A mid-sized manufacturing company approached us with multiple challenges: disconnected data systems, manual inventory tracking, and no predictive maintenance capabilities. Our comprehensive solution transformed their operations.

The Challenge

Operational Inefficiencies

- Manual inventory tracking leading to stockouts and overstock

- Disconnected systems with duplicate data entry

- No predictive maintenance causing unexpected downtime

- Paper-based quality control processes

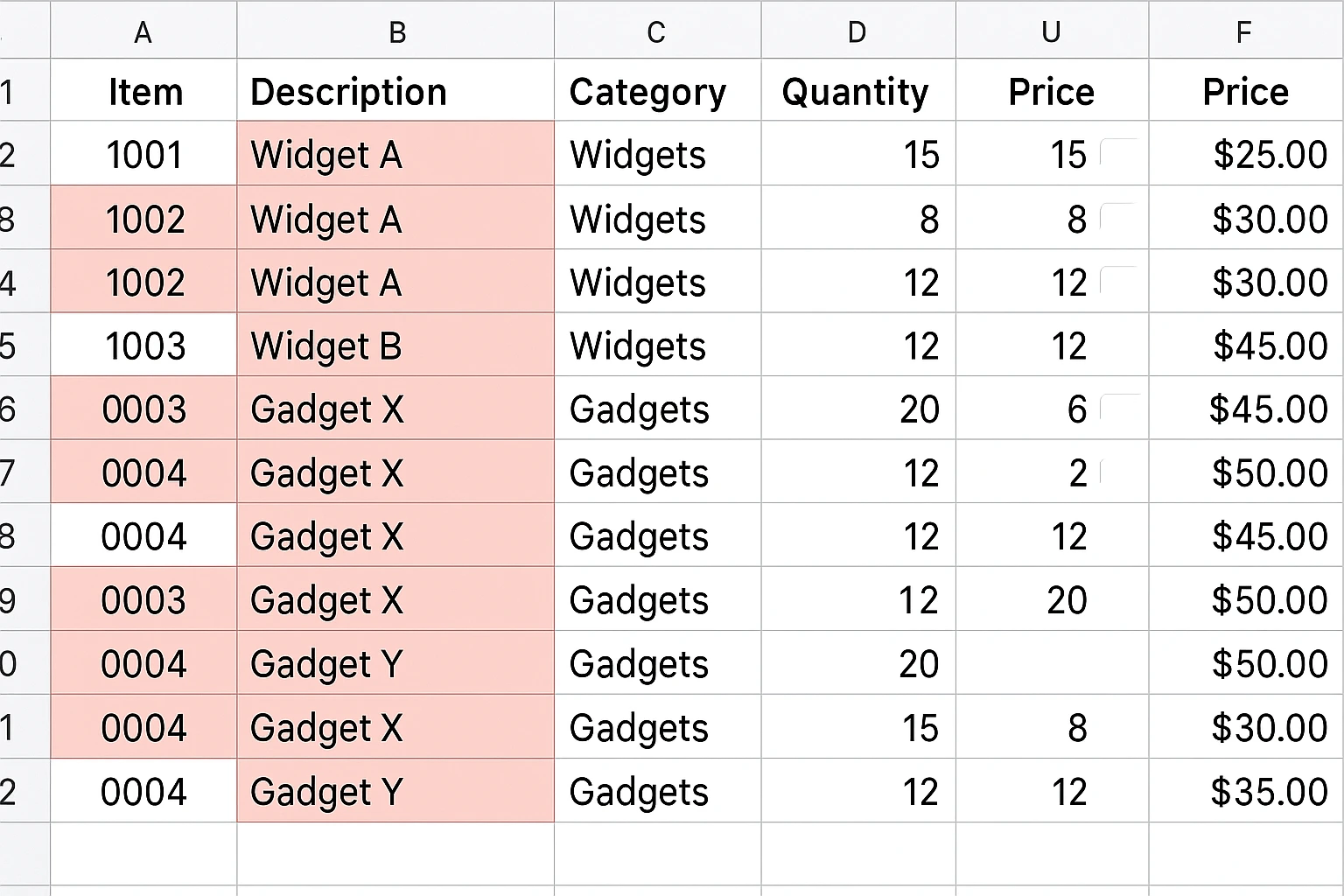

Data Problems

- Customer data scattered across 5 different systems

- 30% duplicate records in customer database

- Inconsistent product naming and categorization

- No real-time visibility into production metrics

Our Solution

A comprehensive digital transformation addressing data, AI, and application needs

Data Cleansing & Integration

Cleaned and unified customer data from 5 systems, eliminated 30% duplicates, and standardized product information across all platforms.

AI Implementation

Deployed predictive maintenance AI to prevent equipment failures and implemented intelligent inventory optimization algorithms.

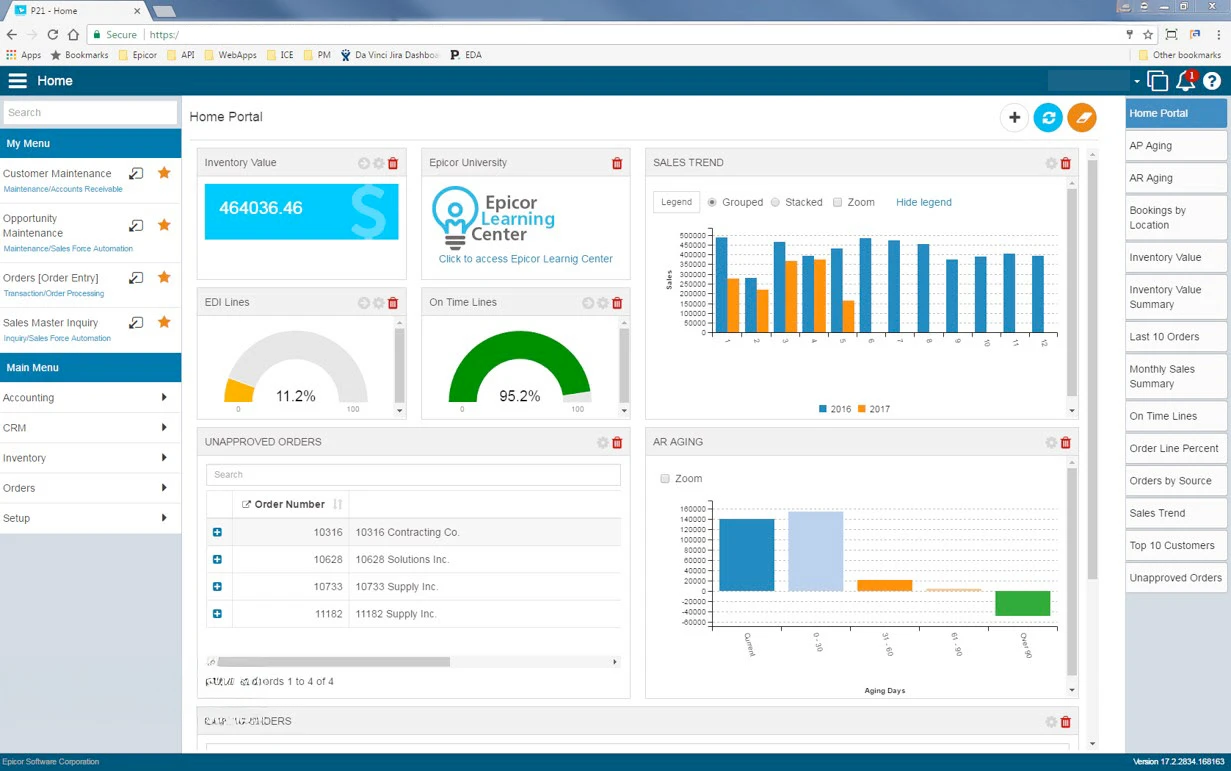

Custom Applications

Built mobile apps for inventory management, quality control checklists, and real-time production dashboards for managers.

Measurable Results

Within 6 months of implementation, the company achieved significant improvements across all key metrics:

Return on Investment

The digital transformation paid for itself within 8 months through measurable savings and efficiency gains

$240,000 Annual Savings

Reduced labor costs, inventory waste, and unplanned maintenance expenses through automation and predictive analytics.

15% Revenue Increase

Improved customer satisfaction and faster order processing led to increased sales and customer retention.

8 Month Payback Period

The entire project investment was recovered through operational savings and increased revenue within 8 months.

Future-Proof Foundation

Built scalable systems that can grow with the business and support future AI and automation initiatives.

Client Testimonial

Ready for Your Digital Transformation?

See how AI, data cleansing, and custom applications can transform your business operations just like they did for Precision Manufacturing. Let's discuss your specific challenges and opportunities.